High Mechanical Strength Perforated Phaj Composite Mesh

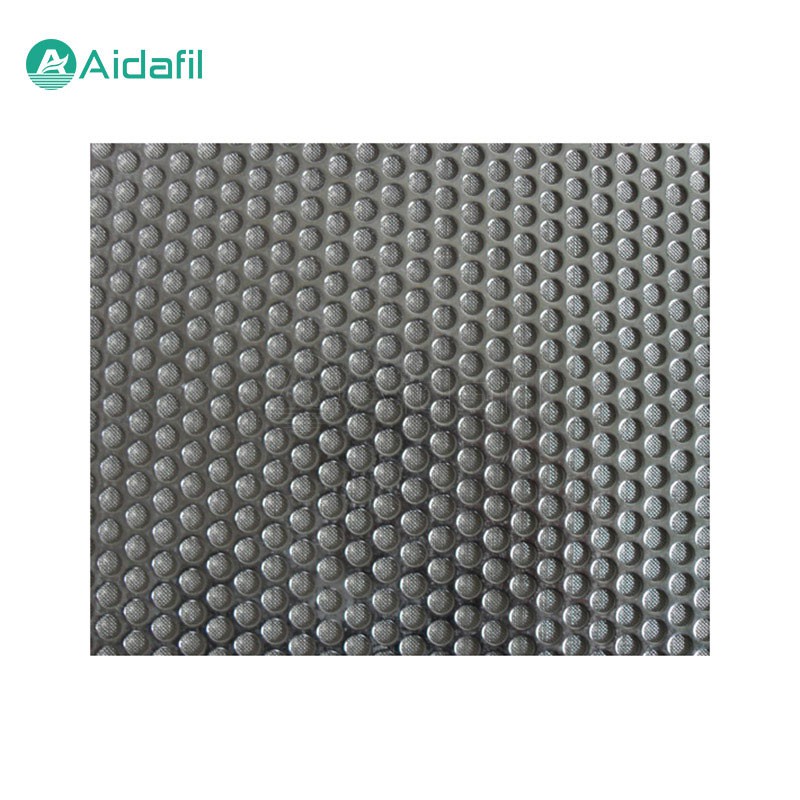

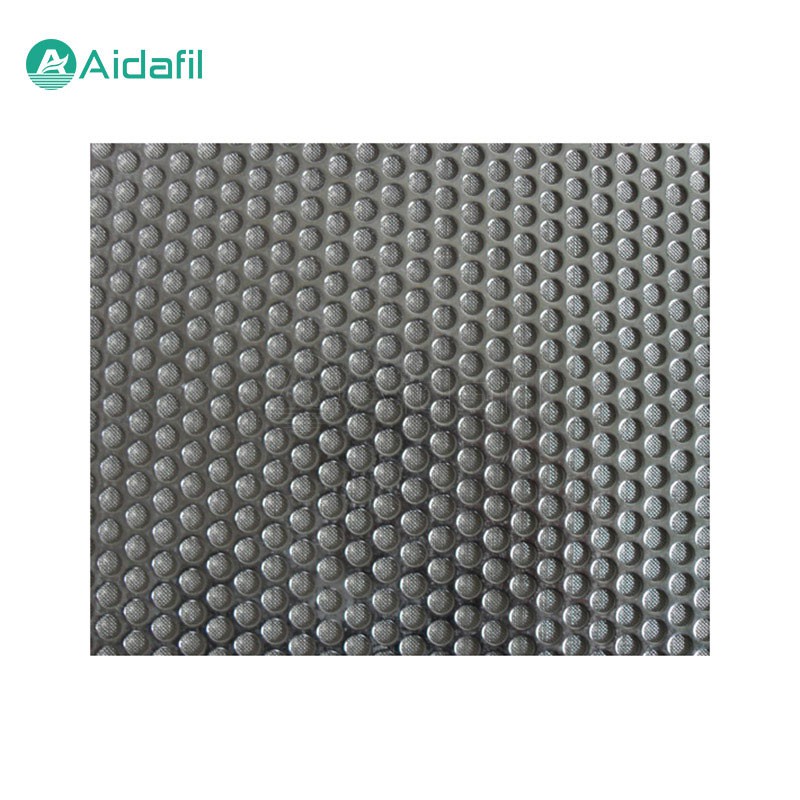

Lub siab mechanical zog perforated phaj composite mesh yog ib hom tshiab ntawm cov khoom lim uas yog sintered rau hauv ib qho kev sib xyaw ntawm cov phaj perforated ntawm cov khoom txheem 304 thiab ob peb txheej ntawm square qhov mesh (los yog tuab mesh). Tus naj npawb ntawm cov khaubncaws sab nraud povtseg ntawm cov khoom siv no thiab cov mesh loj ntawm cov hlau mesh tuaj yeem kho raws li kev siv sib txawv thiab kev siv.

Lub siab mechanical zog perforated phaj composite mesh yog ib hom tshiab ntawm cov khoom lim uas yog sintered rau hauv ib qho kev sib xyaw ntawm cov phaj perforated ntawm cov khoom txheem 304 thiab ob peb txheej ntawm square qhov mesh (los yog tuab mesh). Tus naj npawb ntawm cov khaubncaws sab nraud povtseg ntawm cov khoom siv no thiab cov mesh loj ntawm cov hlau mesh tuaj yeem kho raws li kev siv sib txawv thiab kev siv.

Khoom siv thiab qauv

- Khoom siv: Cov khoom siv txheem yog 304, thiab lwm yam ntaub ntawv xws li 316L tuaj yeem siv tau.

- Structure: Feem ntau yog tsib-txheej qauv, tab sis nws tuaj yeem kho raws li qhov xav tau tiag tiag.

Qhov zoo

1. Lub mesh channel yog du, nrog zoo heev backwashing thiab regeneration muaj nuj nqi, thiab yuav siv tau ntau zaus tom qab ntxuav.

2. Lub zog txhua yam muaj zog, zoo siab tsis kam, zoo rigidity, thiab tuaj yeem siv rau hauv qhov kub thiab txias.

3. Cov nyhuv lim dej zoo, kev ua haujlwm ruaj khov, kub tsis kam, corrosion kuj, haum rau kev lag luam kws tshuaj.

4. Yooj yim los ntxuav, tsis yooj yim rau deform, thiab txo cov nqi zog.

Daim ntawv thov teb

Lub siab mechanical zog perforated phaj composite mesh tau dav siv hauv kev kho dej, dej haus, khoom noj, metallurgy, tshuaj thiab tshuaj industries.

Nta

1. Ntau yam kev pom tseeb. Los ntawm 1μ mus rau 100μ, muaj kev txhim khu kev qha pom.

2. ruaj khov pom tseeb. Vim yog kev tiv thaiv ntawm cov khaubncaws sab nraud povtseg ntawm cov hlau mesh thiab cov txheej txheem diffusion khoom sintering, lub mesh ntawm lub lim txheej tsis yooj yim rau deform.

3. Lub zog zoo. Nws muaj kev kub siab tsis kam thiab mechanical zog.

4. Yooj yim ntxuav. Tshwj xeeb tshaj yog haum rau rov qab ntxuav.

5. Kub kub tsis kam. Nws tuaj yeem tiv taus qhov kub ntawm 480 degree.

6. corrosion kuj. Vim yog siv cov khoom siv SUS316L, nws muaj kev tiv thaiv corrosion siab.

7. Yooj yim rau txheej txheem. Haum rau kev txiav, khoov, stamping, ncab, vuam thiab lwm yam kev ua haujlwm.

Parameters

|

Qauv nab npawb |

Nominal precision (μm) |

Precision siab (μm) |

Gases permeability (L / min · dm2 · kPa) |

Bubbling siab (pa) |

|

ADBSW1 |

1 |

6-7 |

180 |

5300-6000 |

|

ADBSW 2 |

2 |

8-9 |

240 |

4300-5000 |

|

ADBSW5 |

5 |

11-13 |

260 |

3000-3700 |

|

ADBSW10 |

10 |

16-18 |

310 |

2700-3300 |

|

ADBSW15 |

15 |

24-26 |

350 |

2000-2600 |

|

ADBSW20 |

20 |

28-32 |

450 |

1800-2300 |

|

ADBSW25 |

25 |

34-36 |

620 |

1400-1900 |

|

ADBSW30 |

30 |

40-45 |

690 |

1200-1700 |

|

ADBSW40 |

40 |

50-55 |

720 |

1000-1500 |

|

ADBSW50 |

50 |

71-80 |

850 |

900-1200 |

|

ADBSW 70 |

70 |

89-95 |

900 |

700-1100 |

|

ADBSW100 |

100 |

110-120 |

1080 |

650-1000 |

|

ADBSW150 |

150 |

180-200 |

2600 |

550-800 |

|

ADBSW200 |

200 |

260-280 |

2800 |

450-600 |

Cov txheej txheem tsim khoom

Kev tsim cov txheej txheem ntawm lub siab mechanical zog perforated phaj composite mesh feem ntau suav nrog cov kauj ruam hauv qab no:

1. Kev npaj khoom siv. Ua ntej xaiv cov khoom siv hlau tsis zoo, xws li 304 lossis 316L.

2. Punching txheej txheem. Punch lub stainless hlau ntawv los ntawm lub tshuab xuas nrig ntaus los tsim qhov xav tau lub qhov taub thiab qhov sib nrug.

3. Composite sintering. Muab cov ntawv xuas nrig ntaus nrog lub qhov square qhov mesh lossis ntom mesh, thiab tom qab ntawd khov kho ua ke los ntawm cov txheej txheem sintering.

4. Kev kho deg. Kev kho deg ntawm sintered composite mesh, xws li polishing, tu, thiab lwm yam, los txhim kho nws cov tsos zoo thiab kev ua tau zoo.

5. Kev tshuaj xyuas zoo. Kev tshuaj xyuas zoo ntawm cov khoom tiav kom ntseeg tau tias nws ua tau raws li cov qauv tsim nyog thiab cov neeg siv khoom xav tau.

6. Ntim thiab thauj. Ntim cov khoom tsim nyog thiab tom qab ntawd thauj mus rau cov neeg siv khoom.

Kev xeem ua haujlwm

Txhawm rau kom ntseeg tau tias qhov zoo thiab kev ua tau zoo ntawm cov neeg kho tshuab lub zog siab perforated phaj sib xyaw mesh, yuav tsum tau ua ntau yam kev ntsuas kev ua tau zoo, suav nrog tab sis tsis txwv rau:

1. Kev ntsuas qhov tseeb. Los ntawm kev ntsuas qhov me me ntawm cov kua lim dej, qhov pom tseeb ntawm qhov sib xyaw mesh raug ntsuas.

2. Kev sim siab. Los ntawm kev siv qee qhov siab los yog nro, cov neeg kho tshuab lub zog thiab siab tsis kam ntawm cov khoom sib xyaw mesh raug kuaj.

3. Corrosion resistance test. Cov mesh sib xyaw yog muab tso rau hauv cov tshuaj corrosive ntawm ib qho kev xav tau, thiab nws cov corrosion raug soj ntsuam los ntsuas nws cov kev tiv thaiv corrosion.

4. Kev ntsuas kub ua haujlwm siab. Cov mesh sib xyaw yog muab tso rau hauv qhov kub thiab txias ib puag ncig, thiab nws cov kev hloov pauv tau pom zoo los ntsuas nws qhov kub tsis kam.

5. Kev kuaj xyuas thiab rov tsim dua tshiab. Cov mesh sib xyaw yog ntxuav thiab rov tsim dua tshiab, thiab tom qab ntawd qhov kev ntsuas kev ua tau zoo yog rov ua dua los ntsuas nws cov kev tu thiab kev tsim kho dua tshiab.

Kev tu

Txhawm rau txuas ntxiv lub neej kev pab cuam ntawm lub siab mechanical zog perforated phaj composite mesh, nws yuav tsum tau ua kom zoo thiab tswj xyuas, feem ntau suav nrog cov hauv qab no:

1. Kev tu tsis tu ncua. Raws li kev siv, qhov sib xyaw mesh yog ntxuav tsis tu ncua kom tshem tawm cov av thiab impurities ntawm qhov chaw.

2. Tsis txhob hnav ntau dhau. Thaum siv, hnav ntau dhau thiab kev puas tsuaj rau cov khoom sib xyaw mesh yuav tsum zam.

3. Kev tshuaj xyuas tsis tu ncua. Txheeb xyuas qhov zoo thiab qhov zoo ntawm cov khoom sib txuas tsis tu ncua. Yog tias pom muaj qhov txawv txav, nws yuav tsum tau ua raws sijhawm.

4. Cia ib puag ncig. Thaum khaws cov khoom sib xyaw, ib qho chaw qhuav thiab qhov cua zoo yuav tsum tau xaiv kom tsis txhob muaj tshav ntuj ncaj qha thiab av noo.

Vim Li Cas Xaiv Peb

· Cov chaw tsim khoom nrog ntau xyoo kev paub

· Zoo zoo nrog tus nqi sib tw

· OEM & ODM txais tos

· Ntau yam kev them nyiaj tau txais

· Kev pabcuam zoo los ntawm tus thawj coj paub txog

AIDA Philosophy

1. Kev Tswj Xyuas Tswv Yim:

· Txaus siab rau cov neeg siv khoom xav tau --- Kov cov neeg siv khoom, ntseeg peb cov khoom thiab cov kev pabcuam

· Ua kom cov neeg ua haujlwm zoo siab --- Ua raws li cov khoom siv siab dua thiab kev zoo siab ntawm sab ntsuj plig

2. Lub Hom Phiaj Lub Tuam Txhab:

· Tsom ntsoov rau cov neeg siv khoom xav tau, muab kev lim dej zoo tshaj plaws

· Los ua tus khub mus ib txhis nrog cov neeg siv khoom

3. Corporate Vision:

· Ua ib tug thoob ntiaj teb purification kev coj noj coj ua hom

4. Tus nqi:

· Cov neeg siv khoom: Ua raws li qhov kawg ntawm kev paub, txaus siab rau qhov zoo tshaj plaws

· Pab neeg: Kev ntseeg siab, lub luag haujlwm, kev loj hlob, yeej-yeej

· Ua haujlwm: Yooj yim, ua siab dawb, ua haujlwm zoo, mob siab rau

Cim npe nrov: high mechanical zog perforated phaj composite mesh, Tuam Tshoj, Hoobkas, nqe, yuav