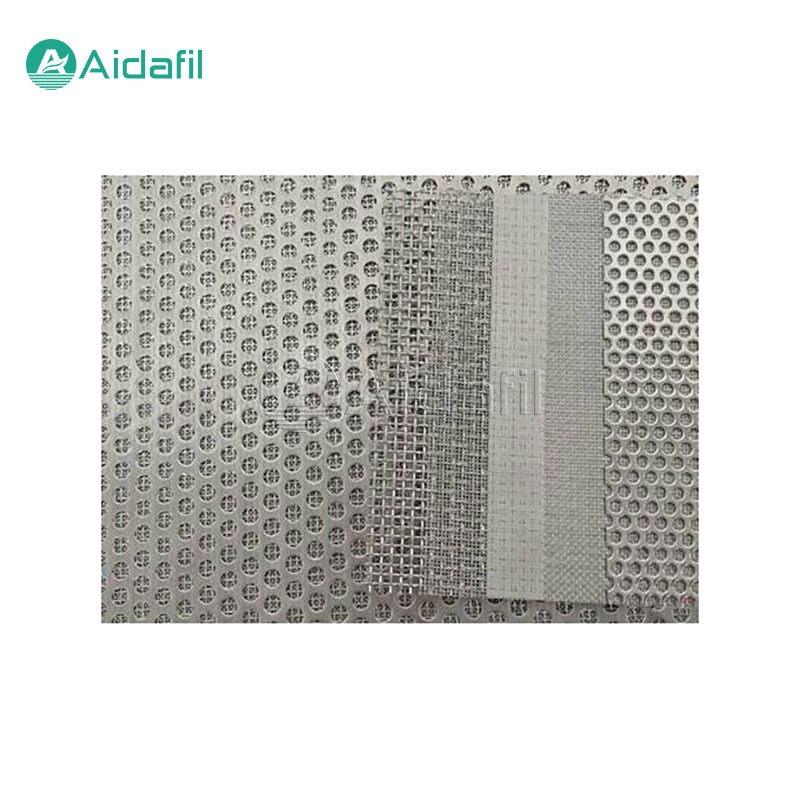

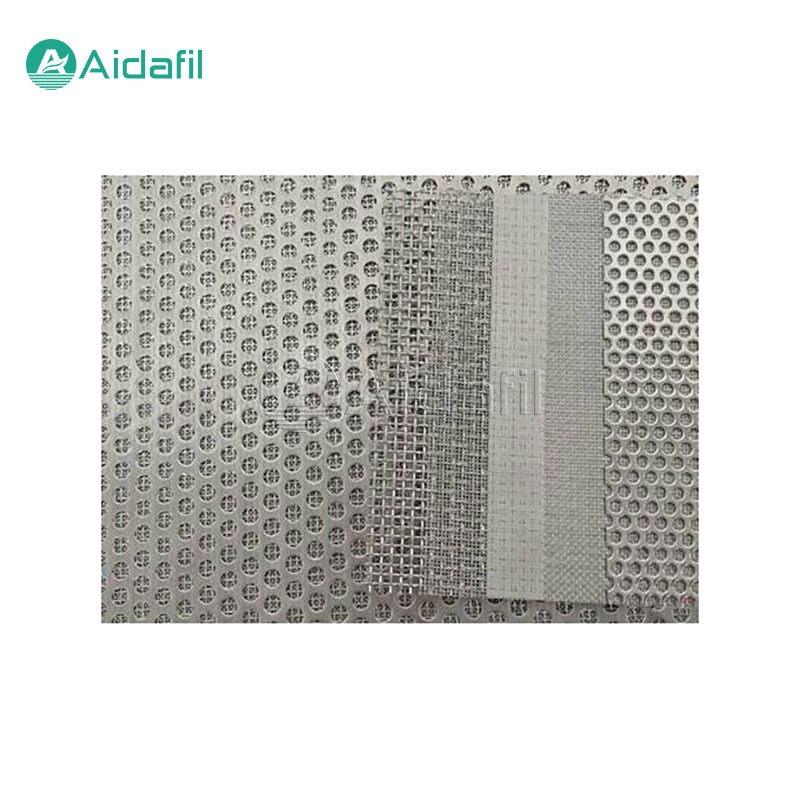

Enhanced Strength Perforated Phaj Sintered Mesh

Lub zog txhim khu kev qha perforated phaj sintered mesh ua ke cov neeg kho tshuab lub zog ntawm cov phaj perforated nrog lub siab pom tseeb ntawm sintered mesh. Lub phaj perforated ua raws li cov pob txha txhawb nqa kom muaj zog txhua yam thiab ruaj khov; ntau txheej ntawm square mesh los yog ntom mesh yog superimposed rau nws kom ua tiav qhov yuav tsum tau pom qhov tseeb thiab flux yuav tsum tau.

Lub zog txhim khu kev qha perforated phaj sintered mesh ua ke cov neeg kho tshuab lub zog ntawm cov phaj perforated nrog lub siab pom tseeb ntawm sintered mesh. Lub phaj perforated ua raws li cov pob txha txhawb nqa kom muaj zog txhua yam thiab ruaj khov; ntau txheej ntawm square mesh los yog ntom mesh yog superimposed rau nws kom ua tiav qhov yuav tsum tau pom qhov tseeb thiab flux yuav tsum tau.

Kev xaiv khoom

Cov khoom siv yooj yim ntawm kev txhim kho lub zog perforated phaj sintered mesh feem ntau yog stainless hlau, xws li 304, 316L thiab lwm yam qauv. Qhov no yog vim hais tias stainless hlau tsis tsuas yog muaj kev tiv thaiv corrosion zoo heev, tab sis kuj tuaj yeem tswj xyuas lub cev thiab tshuaj lom neeg ruaj khov ntawm qhov kub thiab txias. Tsis tas li ntawd, raws li kev thov tshwj xeeb, cov ntaub ntawv ua tau zoo xws li cov nickel-based alloys thiab titanium alloys kuj tseem raug xaiv los ua kom tau raws li cov teeb meem pom hauv qhov chaw huab cua. Xaiv cov khoom tsim nyog yog qhov yuav tsum tau ua ua ntej kom ntseeg tau tias lub sijhawm ua haujlwm ruaj khov thiab pom kev ua haujlwm siab ntawm sintered mesh.

Tus qauv tsim

1. Kev them nyiaj yug ncej: perforated phaj

Raws li cov txheej txheem txhawb nqa ntawm cov khoom sib xyaw sintered mesh, cov phaj perforated feem ntau yog lub luag haujlwm rau nqa cov lim txheej thiab tswj kev ruaj ntseg ntawm tag nrho cov qauv. Nws tus tsim yuav tsum xav txog tej yam xws li lub qhov (lub voj voog, square, pob zeb diamond, thiab lwm yam), qhov pore loj, qhib tus nqi thiab phaj thickness kom tau raws li qhov tshwj xeeb ntawm cov dej hla lub peev xwm thiab lub zog txhua yam. Lub qhov hom thiab layout ntawm lub perforated phaj ncaj qha cuam tshuam rau lub uniform tis thiab zuag qhia tag nrho pom efficiency ntawm lub tom ntej lim txheej.

2. Lim txheej: sintered mesh

sintered mesh txheej yog tus yuam sij rau kev ua tiav high-precision pom. Los ntawm sintering ultrafine hlau hmoov los yog hlau xaim mesh ntawm qhov kub thiab txias, ib tug ntom thiab uniform ntxeem tau qauv yog tsim. Cov txheej txheem sintering tuaj yeem tswj qhov pore loj thiab kev faib tawm, yog li kho qhov tseeb pom tseeb. Raws li daim ntawv thov, sintered mesh tuaj yeem tsim los ua ib txheej txheej lossis ntau txheej txheej. Kev sib txawv ntawm cov mesh loj (mesh loj) thiab cov txheej txheem ntawm txhua txheej tuaj yeem ua tau raws li ntau yam kev xav tau los ntawm kev pom ntxhib mus rau ultra-precision filtration.

Parameters

|

Nominal precision (μm) |

Precision siab (μm) |

Gases permeability (L / min · dm2 · kPa) |

Bubbling siab (pa) |

|

1 |

6-7 |

180 |

5300-6000 |

|

2 |

8-9 |

240 |

4300-5000 |

|

5 |

11-13 |

260 |

3000-3700 |

|

10 |

16-18 |

310 |

2700-3300 |

|

15 |

24-26 |

350 |

2000-2600 |

|

20 |

28-32 |

450 |

1800-2300 |

|

25 |

34-36 |

620 |

1400-1900 |

|

30 |

40-45 |

690 |

1200-1700 |

|

40 |

50-55 |

720 |

1000-1500 |

|

50 |

71-80 |

850 |

900-1200 |

|

70 |

89-95 |

900 |

700-1100 |

|

100 |

110-120 |

1080 |

650-1000 |

|

150 |

180-200 |

2600 |

550-800 |

|

200 |

260-280 |

2800 |

450-600 |

Cov yam ntxwv ua haujlwm

1. High filtration raug

Kev tsim ntawm ntau txheej sintered mesh ua rau nws cuam tshuam cov khoom me me thiab ua tau raws li qhov xav tau ntawm kev pom tseeb.

2. Muaj zog thiab ruaj khov

Cov qauv kev txhawb nqa ntawm cov phaj perforated muab cov cuab yeej zoo heev thiab rigidity, thiab tuaj yeem tswj kev ua haujlwm ruaj khov txawm tias nyob rau hauv qhov sib txawv siab lossis ua haujlwm hnyav.

3. Corrosion kuj thiab kub tsis kam

Cov khoom siv stainless hlau thiab nws cov thev naus laus zis kho saum npoo kom ntseeg tau qhov kev ua haujlwm ntev ntawm cov sintered mesh hauv acidic thiab alkaline ib puag ncig thiab kub kub.

4. Yooj yim los ntxuav thiab tu

Cov qauv ntxeem tau ntawm sintered mesh yog ib qho yooj yim los ntxuav thiab rov qab ntxuav, txo cov nqi tu thiab ncua kev pab cuam lub neej.

5. Yooj yim thiab customization

Qhov pore loj, tus naj npawb ntawm cov khaubncaws sab nraud povtseg, cov ntaub ntawv, thiab lwm yam tuaj yeem hloov kho raws li kev thov tshwj xeeb kom ua tiav cov qauv tsim.

Daim ntawv thov teb

Perforated phaj composite sintered mesh yog dav siv hauv kev kho dej, khoom noj khoom haus thiab dej haus, tshuaj, tshuaj lom neeg kev lag luam, roj av, tsuas, hluav taws xob, tsheb tsim thiab lwm yam lag luam, suav nrog tab sis tsis txwv rau:

- Kev kho dej. Xws li kev haus dej huv, kev kho dej khib nyiab, dej hiav txwv desalination, thiab lwm yam., kom tshem tawm cov teeb meem tshem tawm, cov kab mob thiab cov colloids hauv dej.

- Kev lag luam zaub mov thiab dej haus. Lim cawv, kua txiv hmab txiv ntoo, khoom noj siv mis, thiab lwm yam kom paub meej cov khoom purity thiab kev nyab xeeb.

- Pharmaceutical manufacturing kev lag luam. Ua kom pom tseeb qhov tseeb thiab kev sib cais hauv cov tshuaj purification thiab kev npaj lom neeg.

- Kev lag luam tshuaj thiab petrochemical. Ua lub luag haujlwm tseem ceeb hauv cov tshuaj tiv thaiv nruab nrab pom, roj purification, catalyst rov qab, thiab lwm yam.

Cov txheej txheem tsim khoom

1. Kev kho mob ua ntej

Cov ntaub ntawv raw yog txiav, leveled, ntxuav thiab lwm yam pretreatment kauj ruam los xyuas kom meej ib tug huv si thiab flawless nto nyob rau hauv kev npaj rau cov txheej txheem tom ntej.

2. Txheej txheej

Lub phaj perforated yog siv los ua cov txheej hauv qab, thiab cov hlau hlau mesh ntawm qhov sib txawv mesh yog nteg rau nws nyob rau hauv ib ntus raws li cov qauv tsim los tsim cov txheej txheem ntau txheej. Cov khaubncaws sab nraud povtseg yuav tsum tau zoo sib xws thiab leveled.

3. Sintering

Cov txheej txheem sib sau ua ke tau muab tso rau hauv lub qhov cub sintering thiab ua kom sov rau qhov kub hauv qab lub melting point ntawm cov hlau nyob rau hauv lub tshuab nqus tsev los yog tiv thaiv cua. Cov diffusion thiab kev sib txuas ntawm cov khoom hlau yog siv los ua ib lub cev ntxeem tau sib xyaw. Cov txheej txheem no yuav tsum muaj kev tswj xyuas qhov kub thiab txias, lub sijhawm thiab lub siab kom ntseeg tau tias cov sintering tsis sib xws ntawm txhua txheej kom tsis txhob deformation thiab kev puas tsuaj.

4. Tom qab ua tiav

Lub sintered composite mesh kuj yuav tsum tau mus los ntawm kev txiav, ntug kev, kev kho deg thiab lwm cov kauj ruam kom ua tiav qhov loj me me yuav tsum tau thiab nto tiav. Hauv qee qhov kev siv, kev kho cua sov lossis tshuaj lom neeg kev kho mob kuj tseem yuav tsum tau txhim kho nws cov kev tiv thaiv corrosion.

Vim Li Cas Xaiv Peb

· Cov chaw tsim khoom nrog ntau xyoo kev paub

· Zoo zoo nrog tus nqi sib tw

· OEM & ODM txais tos

· Ntau yam kev them nyiaj tau txais

· Kev pabcuam zoo los ntawm tus thawj coj paub txog

AIDA Philosophy

1. Kev Tswj Xyuas Tswv Yim:

· Txaus siab rau cov neeg siv khoom xav tau --- Kov cov neeg siv khoom, ntseeg peb cov khoom thiab cov kev pabcuam

· Ua kom cov neeg ua haujlwm zoo siab --- Ua raws li cov khoom siv siab dua thiab kev zoo siab ntawm sab ntsuj plig

2. Lub Hom Phiaj Lub Tuam Txhab:

· Tsom ntsoov rau cov neeg siv khoom xav tau, muab kev lim dej zoo tshaj plaws

· Los ua tus khub mus ib txhis nrog cov neeg siv khoom

3. Corporate Vision:

· Ua ib tug thoob ntiaj teb purification kev coj noj coj ua hom

4. Tus nqi:

· Cov neeg siv khoom: Ua raws li qhov kawg ntawm kev paub, txaus siab rau qhov zoo tshaj plaws

· Pab neeg: Kev ntseeg siab, lub luag haujlwm, kev loj hlob, yeej-yeej

· Ua haujlwm: Yooj yim, ua siab dawb, ua haujlwm zoo, mob siab rau

Cim npe nrov: Txhim khu lub zog perforated phaj sintered mesh, Tuam Tshoj, Hoobkas, nqe, yuav